The following is about New product vapor chamber soldering heat sink high efficient cooling buckle radiator related, I hope to help you better understand aluminum skived fin heat sink cnc machined skiving fin heat sink.Material: Aluminum + CopperProduct dimension: 88x68x40mmProduct weight: 0.25 kgFeature: New technology and high efficient coolingSurface treatment: passivationHeat conducting power: 105WProduct Technology: Zipper fin + surface finish

Chip Heat Sink

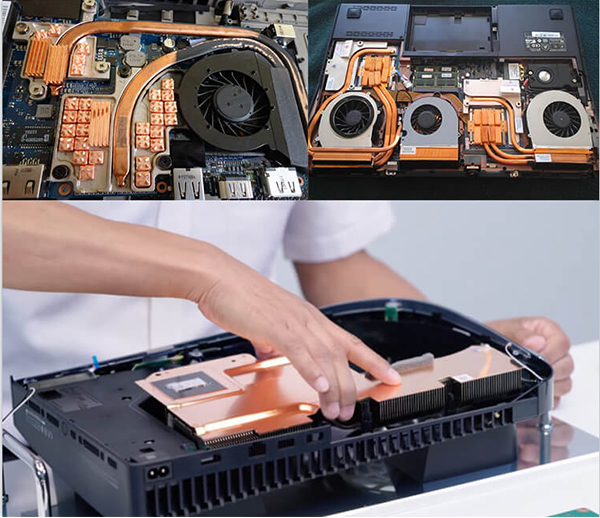

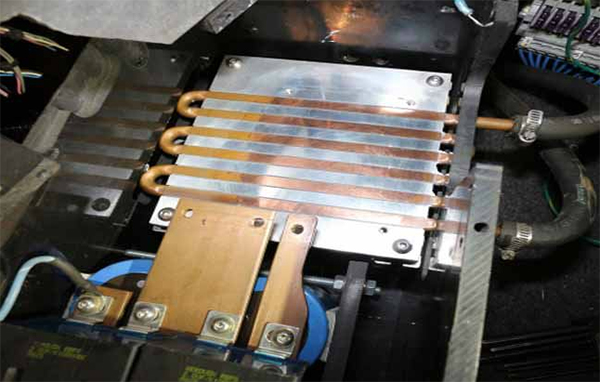

The chip with high integration, especially as the core business processing unit, needs to perform multiple tasks at the same time, and the data processing speed is fast, which is bound to produce relatively high power consumption and heat. This heat must be transferred in time, otherwise the heat accumulates, resulting in a sharp rise in the temperature of the internal environment of the device, resulting in excessive junction temperature inside the chip, resulting in failure. It can cause the device to restart or crash, or the chip to burn out. This leads to the damage of equipment, causing unnecessary losses to users, so chip cooling is very important. For this purpose, the industry usually installs a chip heat sink on the top of the chip which generates more heat, and then provides the thermal design processing system of the device to discharge the heat. For light and small heat sink, usually use silica gel or thermal conductive silica pad directly glued to the top of the chip, but this way is not suitable for large heat sink. Because the weight of the large heat sink itself is heavier, if the chip heatsink is directly glued to the chip, it may bring hidden trouble to the stability and reliability of the chip, or even direct damage to the chip due to transport or external vibration.

Heat sinks with welded feet are used to weld the circuit board. This method is usually in the heat sink diagonal position processing a small platform; One metal welding foot shall be embedded in the platform, and tin shall be attached to the welding foot. Usually, tin shall be coated or pressed on the surface of the welding foot, or tin coated wire shall be directly used, and thermal conductive silicon grease or silica gel shall be coated on the top surface of the chip.

2. Adopt the way of wire fastening installation. The steel wire buckle passes through the middle groove of the profile heat sink, pressing, coating the top surface of the chip with thermal conductive silicon grease or silica gel, the chip heat sink with steel wire buckle placed on the top surface of the chip, flat, the wire buckle at both ends of the hook down, hanging in the ring of the fixed hook welded on the circuit board. In this way, the chip heatsink is fixed.

Product designing and manufacturing of New product vapor chamber soldering heat sink high efficient cooling buckle radiator

Every products of heat sinks needs several process including the drawing design, CNC machining, friction welding stir, soldering, assembly, skiving and extrusion, Testing and finally turn to the step in the surface treatment.

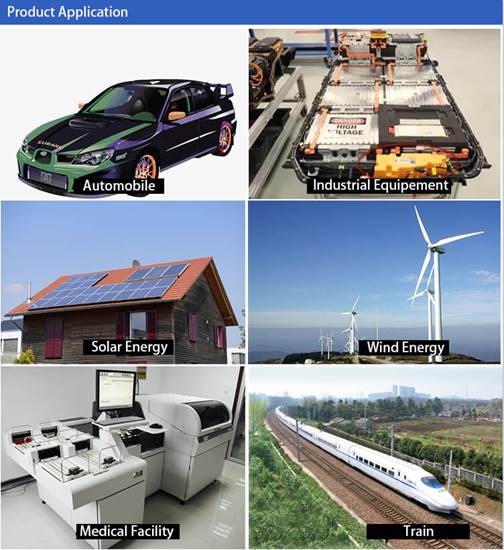

Product application of New product vapor chamber soldering heat sink high efficient cooling buckle radiator

Our heat sinks and water cold plates has been utilized in many of fields, including transportation, CPU computer, servers, Led light, Laser equipment and air condition and so on as long as any electrical product that generate the heat.

So when you are designing the thermal heat sinks or any radiators, there must be some of them may be met your requirement.

Packing details of New product vapor chamber soldering heat sink high efficient cooling buckle radiator

All the heat sinks, water cold plates and heat pipes are packed in the EPE foam and in the carton, the carton itself has the strong protection using the wooden frame for it and finally utilize the Packaging transparent film as it is water proof, some of the larger heat sinks or water cooling plate may adopt the wooden carton due to the special demanding, wooden box inside has the thick EPE that offer great protection from inside and outside knocking!

Our service

1.Once received the inquiry will be quickly replied

2.Keep the product be qualified and price be reasonable and competitive.

3.Fastly arrange production and improve efficiency. Get the goods be finished on time.

4.We can advice the best transportation depends on the goods weight and cubic meter

5.Any questions with the goods we made, we will offer the best solution and technique support.

FAQ

1. Q:Are you trading in company or manufacturer?

A:We are the professional manufacturer of heat sink and water cooling plate

that has much experiences and strong technique team, automatically and mechanized production

2. Q:Have you exported the goods before and to which regions?

A:60% goods in total has exported abroad, to Japan, India ,British, Canada, America and Brazil.

3. Q:How many employees you have?

A:we have about 100 employees ,including sales, purchase ,engineering ,QA ,warehouse and production department.

4. Q:If I agree with the design, can you provide the samples we need?

A:Yes,we can we surely will provide the samples to you for confirmation before mass production. Meanwhile the drawing we could provide if needed

5. Q:What packing you're using and can be assured safety?

A:Every goods are be packed with customized packing ways in normal cartons with tight proof fabric and wooden cartons for great protection,

so it is safe during transportation.

6. Q:If we have any questions with products, can you provide the technique and solution?

A:Every products are fully checked before shipping, if there is problems you're facing, please feel free to let us know, we will offer best solution at once.