There are two kinds of mobile phone heat dissipation: Active heat dissipation and passive heat dissipation. The basic idea is to reduce the thermal resistance of mobile phone heat dissipation, among which (passive heat dissipation) or reduce the calorific value of mobile phone. (Active heat dissipation) is realized by reducing the power consumption and heat of the chip, which is related to the research and development of electronic equipment. Passive heat dissipation is achieved by heat-conducting materials and devices. The components that generate heat in mobile phones are mainly CPU, battery, motherboard, RF front-end, etc. The heat generated by these components will be led into the inter layer with large heat capacity by the heat sink, and then dissipated through the mobile phone shell and the heat dissipation hole.

As electronic products become thinner and thinner, their heat dissipation capacity is limited due to the narrow space inside the body. The main heat sources on smart phones include these five aspects: main chip operation, LCD driver, battery release and charging, CCM driver chip, uneven heat conduction and heat dissipation in PCB structure design.

In order to solve these heat dissipation problems, the current heat dissipation technologies on the market mainly have the following schemes.

1. Graphite sheet heat dissipation: At present, most of the heat dissipation schemes in smart phones adopt graphite sheet heat dissipation scheme, but with the increasing heat dissipation demand of electronic equipment, the heat conduction of single-layer or double-layer graphite sheet can not meet the higher heat dissipation demand.

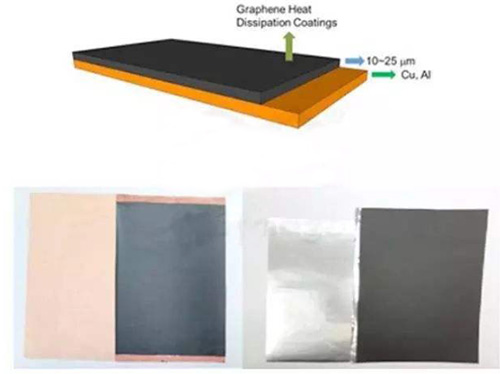

2. Graphene heat dissipation: Graphene has excellent thermal conductivity, which is a known material with high thermal conductivity, and its heat dissipation efficiency is much higher than the current commercial graphite heat sink. Graphene heat dissipation film is very thin, flexible and has excellent comprehensive performance, which makes it possible to develop thin electronic products. Secondly, graphene heat dissipation film has good reprocessability, and can be combined with other thin film materials such as PET according to its application.

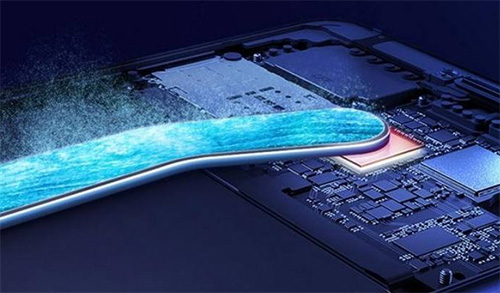

3. Graphene VC vapor chamber: At present, graphene vapor chamber has been born, and its performance can be called another enhanced version of conventional copper-aluminum VC. The vapor chamber is the only cooling device in the industry that can replace flat heat pipe at present, while ordinary liquid-cooled VC can only say that it has the advantage of better compressing the thickness of mobile phone in thinner space, and it is thinner than flat heat pipe, and its comprehensive performance does not lose heat pipe and is a little stronger than heat pipe. It has been widely recognized as an excellent cooling tool in the industry. However, under the curious and bold imagination of human beings, the progress of science and technology has broken through the new achievements of graphene temperature equalization board. It is reported that the graphene temperature equalization board used in mobile phones has a thickness of 280um and an area of 1232mm2, covering the core heating area of the motherboard. The total heat dissipation area is as high as 11588mm2, which greatly improves the heat dissipation efficiency.

4. Graphene vapor chamber is designed by special processing of graphene thermal conductive film. It mainly has the advantages of heat dissipation performance equivalent to VC vapor chamber, weight only half of VC vapor chamber, good flexibility, strong processability and lower cost than VC soaking plate. Yuan Yang Thermal Energy and Graphene Material Factory have reached long-term cooperation and technical mutual assistance, jointly providing better graphene processing technology for radiators and VC soaking plates, providing more heat dissipation solutions for customers, and striving to create more heat dissipation products with better heat dissipation performance and low cost after maintaining or reducing the cost under the curtain of the new era. Thank you very much for client’s support and consultation and discussion on heat dissipation technology.