On March 9th 2020, we’ve gotten an inquiry from a company which dabbled in digital and artificial intelligence, what they needed was a water cooling block in 400W cooling that suitable for a large medical equipment, the size is 40*36*12mm, but they had requirement that cooling device shall not be very big because it would take up many inner spaces for the other devices and accessories, so they hoped us to provide with a cooling solution and they need 13pcs together for connection, they already had model and sent us for evaluation, after we checked on it and said such small in size cooling block, how to promise having 400W cooling capacity? So here we had be in the depth of thinking to come with a solution. Their model size couldn’t change and enlarge or other things, so we rethought a whole day and finally our technical team proposed that what if we did something inside like copper skiving and using current friction stir welding to do such improvement.

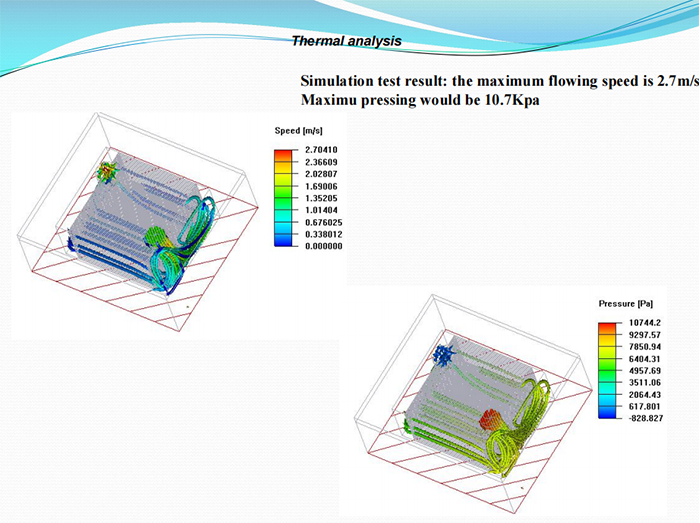

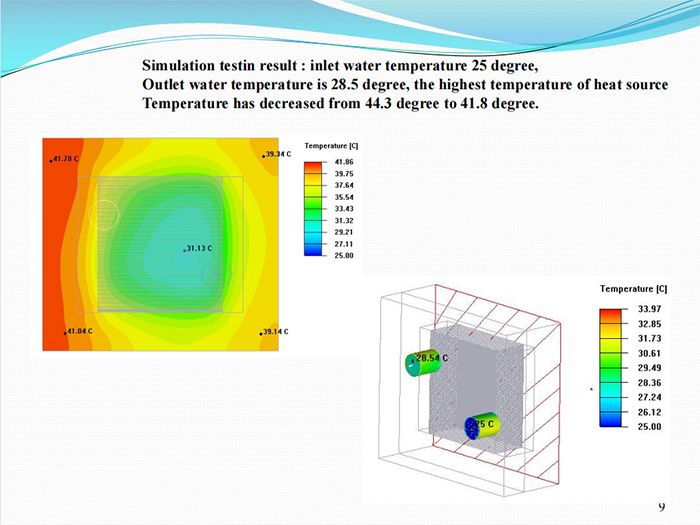

Firstly we would make empty and skiving fin inside and sent back to customers to confirm, after they agreed and our revised model had nothing to worry about interfering their devices, they asked us better if we could give them the simulation result, so we made simulation ourselves and there was a little problem that fins and fin pitch needs to be smaller and more narrow, only left a little bit of space was enough, suggested by simulation engineer from our company, so we redesigned again and finally the result looked great, the highest temperature of heat source Temperature has decreased from 44.3 degree to 41.8 degree.

As we know that nothing can be true if you just imagine, trying is the only method and option for making it come true. However, we failed one time, because copper skiving needs to be very thinner, almost 0.06mm and fin pitch 0.06mm too, this is ok to make but in a such small shape of water cooling block it still had risk. So we miscalculated it and retried again with another block, the second time we did it successfully and third time we failed in friction stir welding because we needed to adjust the tooling fixture in order to hold in tight and easy for welding, So we readjusted again and tried third times, finally we overcame this issue and confirmed its production way. It’s so excited that we finished whole mini type water cooling block and expected performance at the same time, we packed and send to customer, and what their experiment result was also can cool and reached 400W cooling capacity, they told us this was basic requirement and they needed more for their cooling system, means dozens of cooling blocks connected together to consist of a cooling system for one big medical machines. They tested lifetime and water leaking tests in their experiment lab, and it was normal and stable too. So this was a good news for us, because we must tested water leaking and liquid blocking tests before we ship samples, finally we had made agreement that providing more water cooling blocks to them in coming months.