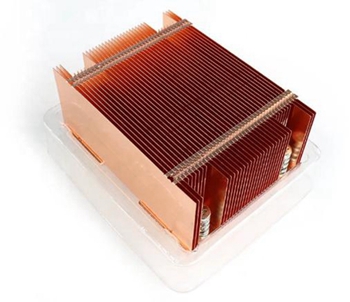

Vapor Chambers, With the continuous improvement of chip power density, VC has been widely used in the heat dissipation of CPU, NP, ASIC and other high-power devices.

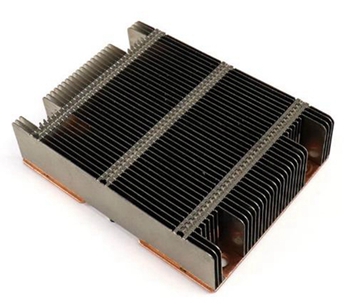

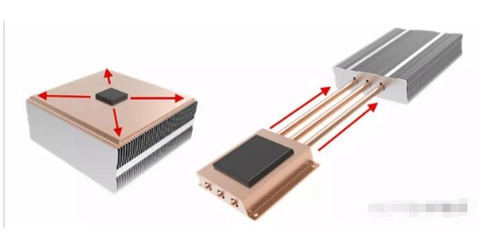

VC radiator is better than heat pipe or metal substrate heat sinks

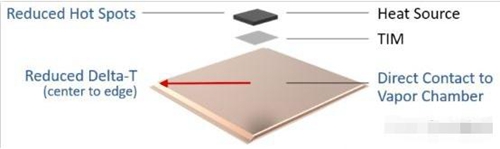

Although VC can be regarded as planar heat pipe, it still has some core advantages. It is better than metal or heat pipe. It can make the surface temperature more uniform (hot spot reduction). Secondly, using VC radiator can make the heat source and VC on heat sinks contact directly,

so as to reduce the thermal resistance; The heat pipe usually needs to be embedded in the substrate.

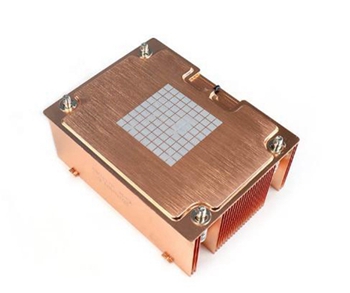

Use VC to equalize temperature instead of transferring heat like a heat pipe

VC spreads the heat and heat pipe transfer heat.

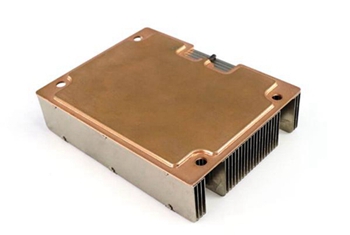

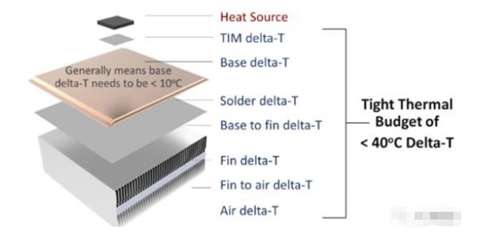

The sum of all △ TS must be less than the thermal budget

This means that the sum of all individual delta TS (from Tim to air) must be lower than the calculated thermal budget. For such applications, a delta-T of 10 ℃ or less is usually required for the radiator base.

The area of VC should be at least 10 times the area of heat source

Like heat pipe, the thermal conductivity of VC increases with the enlargement of length. This means that VC with the same size as heat source has almost no advantage over copper substrate. An experience is that the area of VC should be equal to or greater than ten times the area of heat source. In the case of large thermal budget or large air volume, this may not be a problem. In general, however, the basic bottom surface needs to be much larger than the heat source.