What is welding effect for the heat sink?

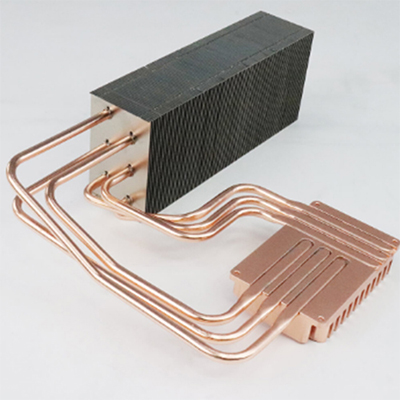

The welding is been a important process for the heat pipe radiator or we can say heat sink module, its features like high power, reliable cooling function and durable in lifetime using, such advantages has given the welding heat sink to be wide application and serves as significant cooling device for communication equipment and larger industrial machines, the heat pipes can be flexible in quantity to add four, six or ten pcs, the welding not only can fix heat pipes, but also can be a role as transporting the heat conductivity. The welding soldering paste can be chosen low temperature or medium temperature.

Copper heat sink for welding advantages as following:

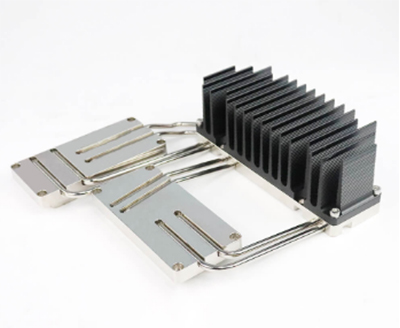

1. High density fin, heat dissipation area, light weight. For soldering single fin, the groove can be processed on the bottom plate to insert the fin into the groove for welding. The density of the fin can be up to 1mm and the height can be up to 150mm.

2. The plate can be machined in a complex way, and can be embedded with heat pipes or vapor chamber, greatly increasing the average temperature.

3. The surface of copper welding heat sink will not be oxidized by medium temperature machining.

4. The welding heat sink copper shape is flexible, which can easily process, install hole position and device avoiding position.

5. Low mold cost, from mini heat sink to large heat sink can be quickly mass production.

6. High reliability, has been widely used in IT equipment and communication equipment heat dissipation.

7. For surface treatment, copper can be welded only after nickel plating, red copper can be welded after rust and oil removal

The fins can be folded fin, L-fin, zipper fin, or fins with heat pipe, and the material is generally AL6063, AL6061, C1100, etc.

According to the material, the welding heat sink can be divided into copper welding heat sink, copper soldering heat sink, copper&aluminum composite soldering heat sink, zipper fin welding heat sink, heat pipe soldering heat sink. According to the process, welding heat sink can be divided into high temperature soldering and low temperature welding. For medium temperature welding heat sink need 160-170 degrees to weld. Commonly used welding process is low-temperature soldering, low-temperature welding heat sink temperature between 110-135 degrees, basically no deformation, can be process with high precision processing, can be used with any equipment.

Our technical service:

We offer technical service that providing the thermal cooling design and heat pipes bending structure,both we can also evaluate availability and production capacity. Yes, although it might need tooling for soldering, we can design low cost and useful tooling for production, you may leave your message of your requirement and tell us what you need for your current radiators, we believe more discussion can solve problems easier and lead to a solution. Thanks for reading!